Corporate

philosophy

Application controls everything for recycling

Our integrated manufacturing method is a system that can provide applications that are suitable for the post consumer bottles.

Ensuring the source history is one of the important factors of quality control in the recycling business, and our integrated manufacturing method represents an optimum production system for securing traceability.

Quality

policies

As a PET recycling company, Utsumi develops various technologies and to contribute to the growth of the plastic-bottle recycling business by actively pushing forward the development of such applications. The organization attempts to understand customer needs in relation to recycling products and, together with customers, create a business that contributes to ECOLOGY (protecting the environment) by producing products and creating environments that are quick to respond to such needs.

- Produce rPET products that are safety and hygiene assured, using post consumer bottles that are applied to foodstuffs, collected according to the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging.

- Create a work environment where tidiness and cleanliness are well-managed.

- Develop a product that is suitable for recycling, suggest the plan to customers and materialize it.

- Place importance on considering the environment and attempt to manage the use of controlled substances as it concerns environmental protection.

- Aim to equalize and improve the quality of recycled products and focus all the resources of the company on the improvement of technology and the training of personnel.

- Continuously improve the effectiveness of the quality management system.

March 2, 2009

Masaaki Utsumi, CEO

Company

profile

| Trade name | Utsumi Recycle Systems Inc. |

|---|---|

| Representative | Masaaki Utsumi, CEO |

| Business content | Overall PET resin recycling (integrated manufacturing up to the final product)

Primary services

|

| Established | July 30, 1993 |

| Capital | ¥341,500,000 |

| Number of employees | 158 (as of the end of May 2023) |

| Qualifications acquired |

|

| Terepthalic Acid and Ethylene Glycol(REACH/ECHA)[Registered July 2021] | |

| Opinion for recycled PET Products (EFSA) |

|

| Green Partner Certification of Sony corporation | |

| Approved as a specified exporter (AEO) |

Offices

Business bases

-

Head office

Address

Sakaisujihommachi TF Bld 8F, 2-4-27, Kyutaromachi, Chuo-ku, Osaka-city, Osaka, 541-0056 JapanTEL: (06) 6261-5511

FAX: (06) 6261-5522Sakaisuji-Hommachi, Sakaisuji/Central Line, Osaka Municipal Subway: Exit 11, a 1-minute walk

-

Tokyo Office

Address

Oak Bld 207, 6-9-7, Takenotsuka, Adachi-ku, Tokyo, 121-0812 JapanTEL: (03) 5851-9061

FAX: (03) 5851-9062Takenotsuka, Tobu Skytree line, East exit, a 3-minute walk

-

Kyushu Office

Address

Sunshine 30, Bld 303, 5-2-1, Shirakibaru, Onojo-city, Fukuoka, 816-0943 JapanTEL: (092) 586-7447

FAX: (092) 586-7448Shirakibaru, Nishitetsu Tenjin Omuta Line: 400 m to the northeast from Exit 1

Production and distribution bases

-

Sennan Factory

Address

8-2-5, Tarui, Sennan, Osaka, 590-0521 JapanTEL: (072) 485-0059

FAX: (072) 480-2389Tarui, Nankai Main Line: 1,000 m to the northeast

-

Rinku Factory

Address

4-11, Rinkuuminamihama, Sennan, Osaka, 590-0535 JapanTEL: (072) 484-1682

FAX: (072) 484-1683Okadaura, Nankai Main Line: 500 m to the west

-

Rinku Office

Address

4-3, Rinkuuminamihama, Sennan, Osaka, 590-0535 JapanTEL: (072) 484-1682

FAX: (072) 484-1683Okadaura, Nankai Main Line: 500 m to the west

Group companies

-

UR Chubu Inc.

Address

503-6, Shimozue, Komaki-city, Aichi, 485-0825 JapanTEL: (0568) 42-2911

FAX: (0568) 42-2912Komaki, Meitetsu Komaki Line: 2 km to the east

-

APET West Corporation

Address

4-11, Rinkuuminamihama, Sennan, Osaka, 590-0535 Japan (in our Rinku Factory)TEL: (072) 434-8078

FAX: (072) 434-8017Okadaura, Nankai Main Line) Station: 500 m to the west

-

URS Harima Inc.

Address

2-13-58, Araichoshinhama, Takasago, Hyogo, 676-0008 Japan

TEL (079)497-5910

FAX (079)497-5911Arai, Sanyo Dentetsu Main Line: 1.6 km to the southwest

-

URS Shiga Inc.

Address

1680-1, kannondaira, Toriihira, Hino-cho, Gamo Gun,Shiga,529-1618 JapanHino, Omi Railroad Main Line:6km to the northeast

-

URS Aqua Inc.

Address

Sakaisujihommachi TF Bld 8F, 2-4-27, Kyutaromachi, Chuo-ku, Osaka-city, Osaka, 541-0056 JapanSakaisuji-Hommachi, Sakaisuji/Central Line, Osaka Municipal Subway: Exit 11, a 1-minute walk

International partners

- S & U Corporation (manages recycled raw PET materials; Seoul, Korea)

- PT.ecofiber (produces recycled PET fiber; Tangerang, Indonesia)

History

~2015

-

1993.07

Established Utsumi Kikaku Corporation (original company name)

-

1996.10

Newly constructed Sennan Factory in Sennan, Osaka

-

1999.04

Joined the Japan PET Tray Association

-

2000.05

Financed S & U Corporation (Korea)

-

2000.11

Newly constructed Komaki Factory in Komaki-city, Aichi

-

2000.12

Acquired the land and building for creating distribution warehouses with business expansion (Sennan, Osaka)

-

2001.02

Moved the organization’s head office for expanding business (Uchihonmachi, Chuo-ku, Osaka-city)

-

2001.05

Increased the organization’s overall capital to ¥341,500,000

-

2001.11

Won the Osaka Frontier prize, a management innovation encouragement special prize, awarded by the Governor of Osaka

-

2002.10

Changed the company name to Utsumi Recycle Systems Inc.

-

2004.04

Newly constructed Rinku Factory in Sennan, Osaka

-

2005.07

Opened Tokyo Office

-

2009.06

Acquired Green Partner certification

-

2009.09

Opened Kyushu Office

-

2010.01

Opened Komaki Office

-

2011.12

Reorganized Komaki Factory as a subsidiary (UR Chubu Inc.)

-

2012.03

Acquired Global Recycle Standard (GRS) certification

-

2012.05

Acquired NOL # 159 from the US Food and Drug Administration (FDA)

-

2012.07

Acquired “Specified Research and Development Plan” certification of “the small- and medium-size manufacturing advancement method” from the Kinki Department of Economy and Industry

-

2012.09

Acquired ISO9001:2008 certification (Excluding group companies)

-

2013.03

Moved the organization’s head office for expanding business (Kyutaromachi, Chuo-ku, Osaka-city)

-

2013.04

Financed PT.ecofiber (Indonesia)

-

2013.07

Received a grant in the form of a “subsidy for operating the cost of a program to promote investment in cutting-edge facilities for taking measures against strong yen and energy constraints for FY 2012”

-

2014.05

Borrowed a ¥250 million capital-related loan from Japan Finance Corporation as a capital spending fund

-

2016.01

Established APET West Co., Ltd. jointly with Chuo Kagaku Co., Ltd. in the Rinku Factory.

-

2016.02

Registered a voluntary standard with the Japan PET Tray Association for CITECH pellets (AFDA)

2017~

-

2017.08

Shifted to ISO9001:2015 (Excluding group companies)

-

2018.02

Installed a no. 8 pellet machine (subsidy program for the operating costs of carbon dioxide emissions suppression measures for FY 2017)

-

2018.04

Registered a voluntary standard with the Japan PET Tray Association for CITECH sheets

-

2018.11

Registered a voluntary standard with the Japan PET Tray Association for CITECH flakes (AFDA)

-

2019.02

Added a second manufacturing line in the UR Chubu Inc. subsidiary

-

2019.02

Installed an optical classifier in the UR Chubu Corporation subsidiary (subsidy program for the operating costs of carbon dioxide emissions suppression measures for FY 2018)

-

2019.06

Acquired the proprietary rights for the Rinku Factory site

-

2019.09

Received a subsidy for the operating costs of carbon dioxide emissions suppression measures for FY 2018 (no. 2 revision)

-

2019.09

Established a business alliance with CHORI Co., Ltd. (Osaka-city) related to the production of pellets

-

2020.02

Installed optical sorters and other equipment at the Rinku Factory and its subsidiary UR Chubu Inc. ((No. 2 amendment) subsidy program for the operating costs of carbon dioxide emissions suppression measures for FY2018)

-

2020.02

Installed wind power sorters and other equipment at subsidiary UR Chubu Inc. (subsidy program for the operating costs of carbon dioxide emissions suppression measures for FY2019)

-

2020.06

Formed a business alliance with Mitsubishi Corporation and Mitsubishi Corporation Plastics Ltd. regarding PET flake manufacturing.

-

2020.07

Established Toyotsu Pet Recycle Systems Corp. in Gamo-gun, Shiga in collaboration with Toyota Tsusho Corp., Chuo Warehouse Co.,Ltd., etc.

-

2020.11

Installed alkaline cleaning tank equipment and other equipment at Rinku Factory (subsidy program for the operating costs of carbon dioxide emissions suppression measures for FY2019)

-

2021.07

EU REACH registration of ethylene glycol and terephthalic acid in ECHA

-

2021.10

Completed construction of PET flake manufacturing plant for subsidiary URS Harima Inc., in Takasago-city, Hyogo

-

2021.10

Obtained EFSA Opinion for recycled PET products

-

2022.04

Completed construction of Rinku office and warehouse in Sennan-City, Osaka

-

2022.06

Completed construction of PET flake manufacturing plant for subsidiary URS Shiga Inc., in Gamo-gun, Shiga

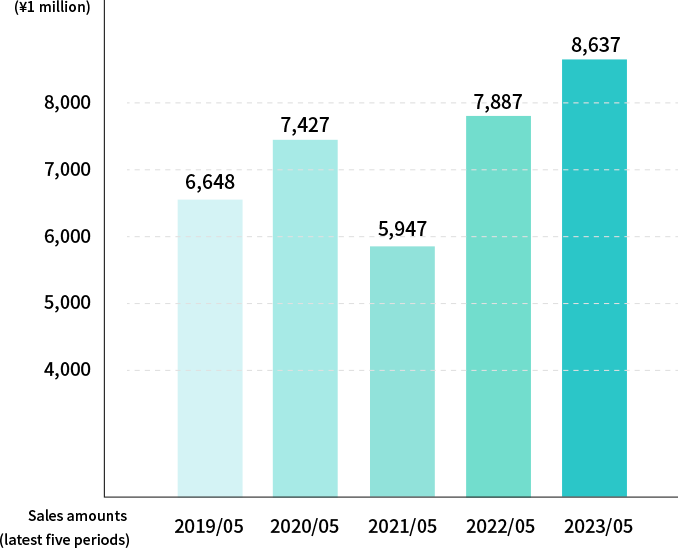

Achievements

| Sales amounts (latest five periods) | 26th period (May 2019) |

27th period (May 2020) |

28th period (May 2021) |

29th period (May 2022) |

30th period (May 2023) |

|---|---|---|---|---|---|

| (¥1 million) | 6,648 | 7,427 | 5,947 | 7,887 | 8,637 |