about

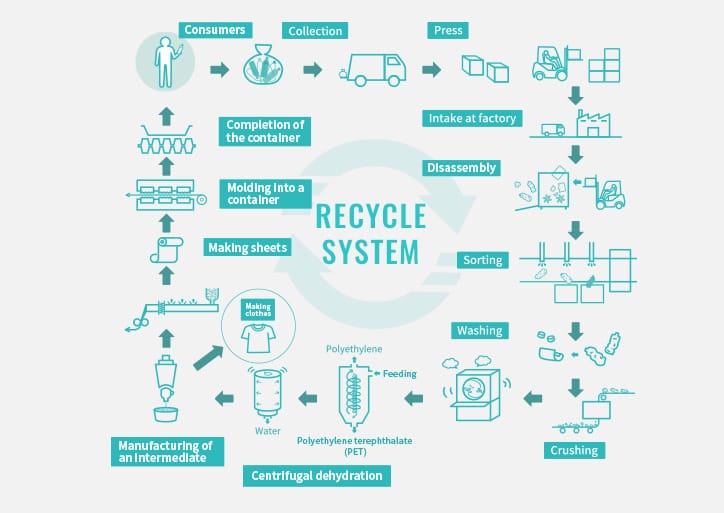

Utsumi recycles polyethylene terephthalate (PET) bottles using the integrated manufacturing system, in which all steps, from the bottles collection to the final product, are managed by one company.

All steps, from the bottles collection to final products are executed by one company; therefore, our system is superior in terms of traceability and safety.

▼Certification・Accreditation

- ・FDA – NOL No.159

- ・REACH – Ethylene Glycol , Terepthalic Acid

- ・EFSA – No.6869、No.7278

- ・Green Partner Certification of Sony corporation – Pellet , Sheet

- ・AEO(Authorized Economic Operator) Program – Authorized Exporter

Three value-regenerating

characteristics

-

One company manages the entire process, from the bottles collection to the production.

Integrated manufacturing system

This system performs all the production steps, from the bottles collection to the final product, within one company. Utsumi introduced this system for the first time in Japan.

-

Can be recycled multiple times

Complete recirculation

system methodWe acquired a patent of a technology that can recycle resins multiple times with the SUPERCLEAN facility that can regain the original physical properties of the disintegrated resins, as well as a no-objection letter (NOL; no. 159) from the US Food and Drug Administration (FDA).

-

By complete quality control and information disclosure

Safe and secure high quality

Using the integrated manufacturing system, it is possible to provide all historical information related to the recycling process.

services

To respond requests from our customers, we provide various products from post consumer PET bottles.

-

Small PET pieces that are crushed, and washed PET bottles, are transformed into small pieces called PET “flakes”. These completed PET flakes can be processed to pellets, sheets, and molded pieces.

-

Flakes are processed into small granules following melting, which are referred to as pellets. By removing foreign substances and making the shape uniform during the manufacturing process, stable quality can be achieved in the use of pellets as raw material.

-

Polyethylene terephthalate (PET) flakes that are processed into a thin gauge sheet after melting are known as PET sheets. These sheets are used as raw material in a broad range of fields, e.g., as parts, trays for electric equipment and automobiles, and as food containers.

-

This is the product that is produced when the sheet is processed in a mold. Familiar use include the trays for eggs and fruit, and mushrooms.